1. Highlights

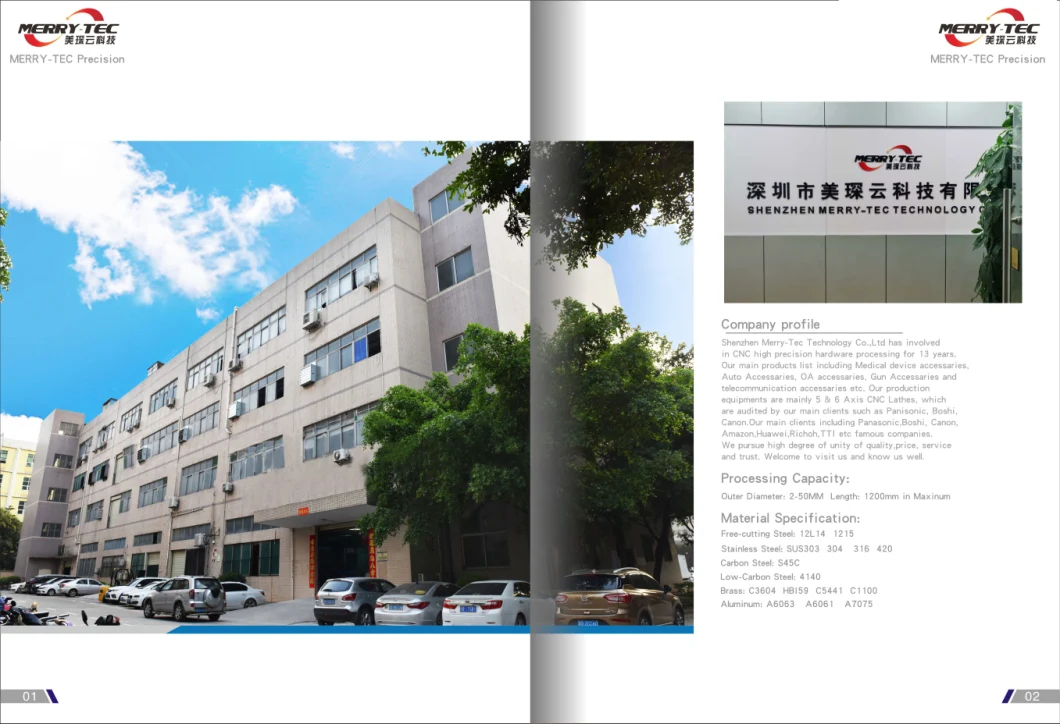

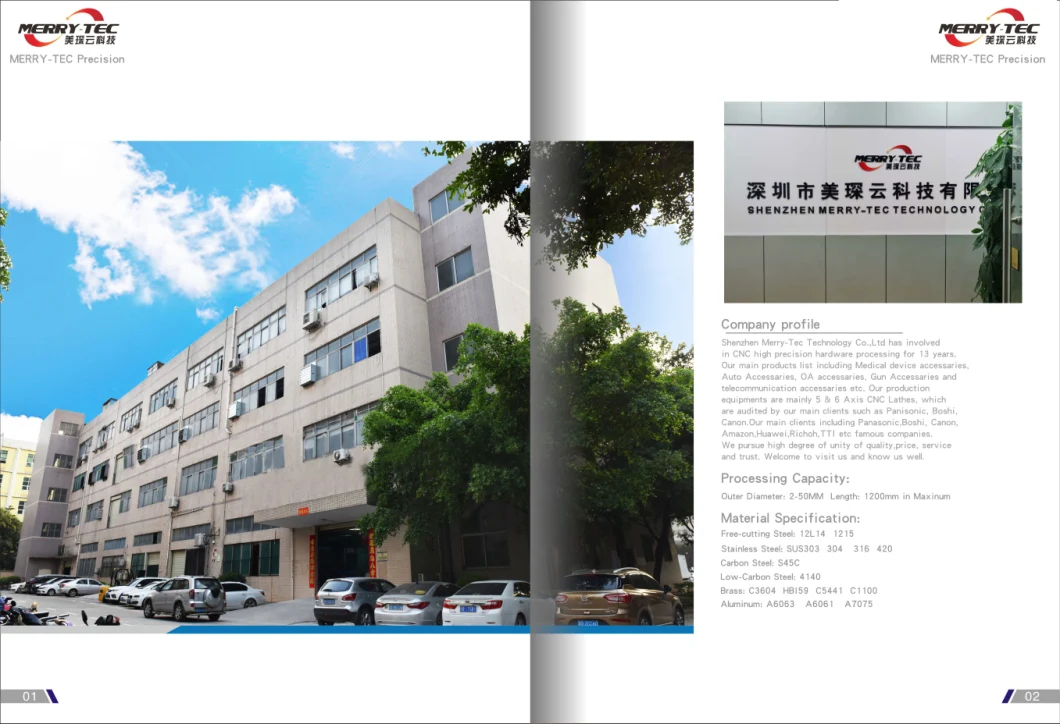

a. 13 years of CNC machining experiences.

b. OEM for Panasonic, Epson,Conon, TTI ect famous companies for more than ten years.

c. Quality, Price and Service in one, Sincerity is the first.

2. Product Description

3.What is the CNC Machining Process?

1.The CNC machining process is to compile a part's CNC machining program according to the original conditions such as the part drawing and process requirements, and input it into the CNC system of the CNC machine tool to control the relative movement of the tool and the workpiece in the CNC machine tool to complete the processing of the part.

2.The main content of CNC machining process:

Step 1: understand the technical requirements of the drawing, such as dimensional accuracy, form and position tolerance, surface roughness, workpiece material, hardness, processing performance and number of workpieces, etc.;

Step 2: Perform process analysis according to the requirements of the part drawings, including the structural processability analysis of the parts, the rationality analysis of materials and design accuracy, and the approximate process steps;

Step 3: Work out all the process information needed for processing according to the process analysis-such as: processing process route, process requirements, tool trajectory, displacement, cutting amount (spindle speed, feed, depth of cutting) and Auxiliary functions (tool change, spindle forward or reverse, cutting fluid on or off), etc., and fill in the processing procedure card and process card;

Step 4: according to the part drawing and the crafted content, and then carry on the numerical control programming according to the instruction code and program format stipulated by the numerical control system used;

Step 5: Input the programmed program into the numerical control device of the numerical control machine tool through the transmission interface. After adjusting the machine tool and calling the program, the parts that meet the requirements of the drawing can be processed.

a. 13 years of CNC machining experiences.

b. OEM for Panasonic, Epson,Conon, TTI ect famous companies for more than ten years.

c. Quality, Price and Service in one, Sincerity is the first.

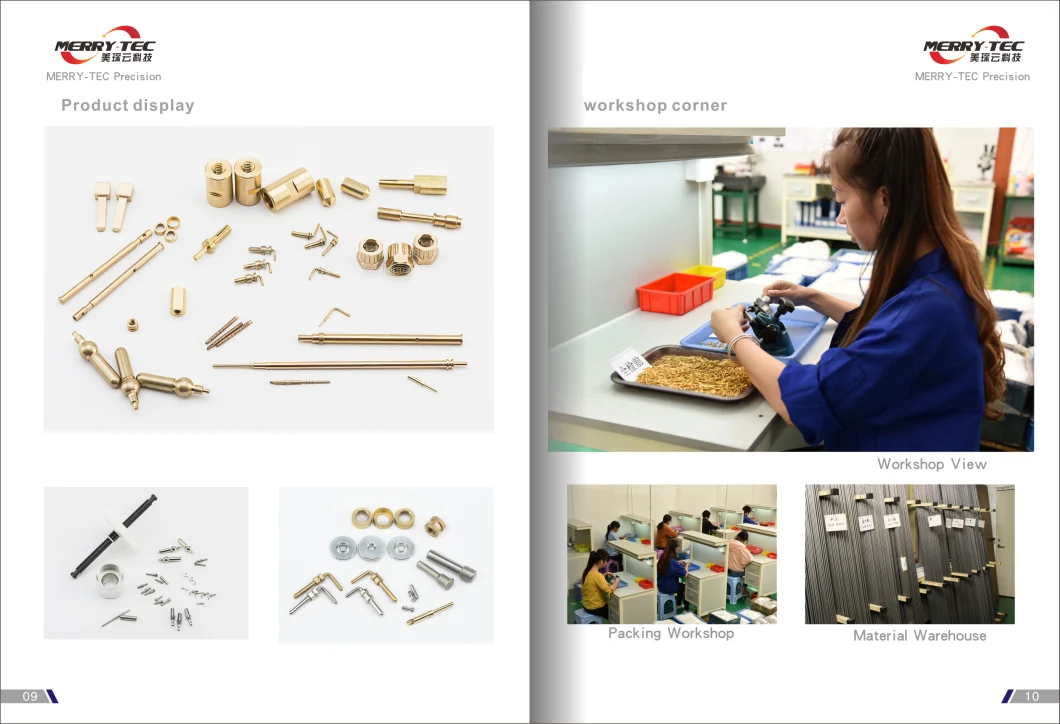

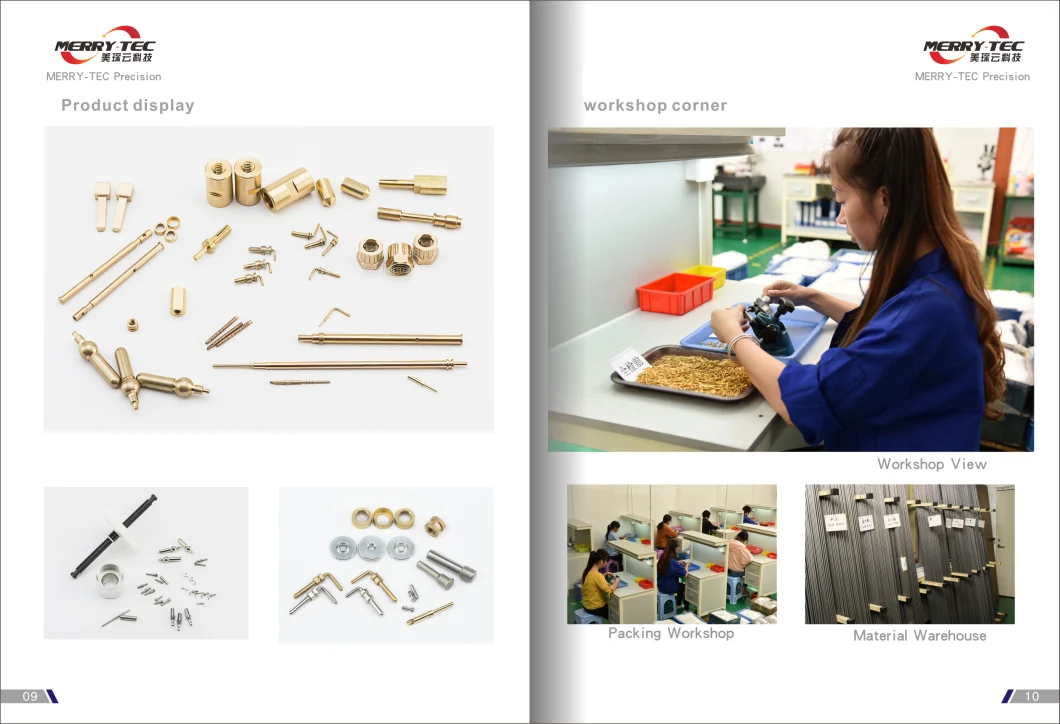

2. Product Description

| Product Name | medical OEM processing, pure titanium alloy, preformed abutment, composite abutment, personalized abutment |

| Material | titannium alloy/ stainless steel |

| Tolerance | ±0.01 - ±0.005mm |

| Surface treatment | according to requirements |

| Processing machine | mainly 5/6 axis automatic Lathe |

| Processing capacity | 500000/month |

| QC system | 100% inspection before packing |

| Warranty | we bear quality issues caused by us, refund back or reproduce. |

3.What is the CNC Machining Process?

2.The main content of CNC machining process:

Step 1: understand the technical requirements of the drawing, such as dimensional accuracy, form and position tolerance, surface roughness, workpiece material, hardness, processing performance and number of workpieces, etc.;

Step 2: Perform process analysis according to the requirements of the part drawings, including the structural processability analysis of the parts, the rationality analysis of materials and design accuracy, and the approximate process steps;

Step 3: Work out all the process information needed for processing according to the process analysis-such as: processing process route, process requirements, tool trajectory, displacement, cutting amount (spindle speed, feed, depth of cutting) and Auxiliary functions (tool change, spindle forward or reverse, cutting fluid on or off), etc., and fill in the processing procedure card and process card;

Step 4: according to the part drawing and the crafted content, and then carry on the numerical control programming according to the instruction code and program format stipulated by the numerical control system used;

Step 5: Input the programmed program into the numerical control device of the numerical control machine tool through the transmission interface. After adjusting the machine tool and calling the program, the parts that meet the requirements of the drawing can be processed.